Everything You Need to Know About Subfloors

What is a Subfloor?

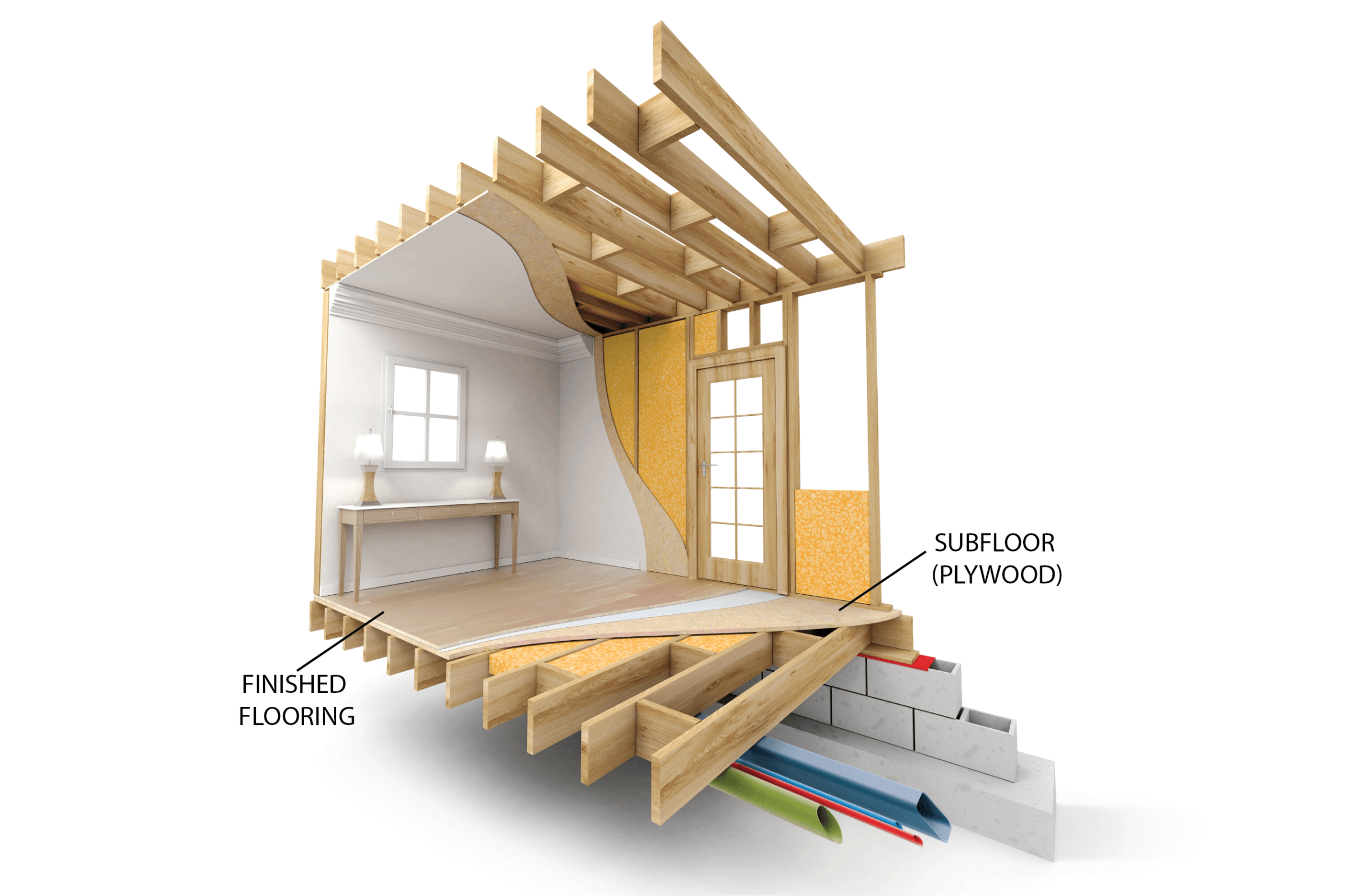

The subfloor is the structure that lies between the floor joists of a home and the finished flooring (hardwood, LVP, etc). The subfloor creates a foundation and provides support for the finished flooring and identifying what type of subfloor you have is key before making your flooring purchase.

Types of subfloors include:

1. Plywood

2. Oriented Strand Board (OSB)

3. Particle Board

4. Concrete

1. PLYWOOD

The most common and cost-effective subfloor is Plywood. Plywood provides a stable foundation and is the most commonly installed subfloor in residential homes. Most flooring types including solid hardwood, engineered hardwood, and luxury vinyl plank can be installed on top of plywood. It is also the most suitable subfloor type for hardwood floors.

Depending on the specific guidelines of each product, solid and engineered hardwood floors can be floated, nailed, or glued onto a plywood subfloor. A floating installation is the most efficient method and involves loose laying the floor planks and locking them together with glue in their tongues and grooves. The more common installation types for both solid and engineered floors are nailing / stapling or gluing down planks directly onto the plywood.

Harper Floors' LVP floors (WPC, SPC, ESPC) are floating floors and and approved for installation on top of any hard and leveled subfloor type, including plywood.

2. ORIENTED STRAND BOARD (OSB)

Oriented Strand Board, or OSB, is another widely used subfloor. It has a flat, smooth surface, unlike the surface of plywood with minor bumps.

Hardwood and LVP floors are approved for installation on top of OSB subfloors. Hardwood is installed by nailing / stapling, or gluing, while LVP floors would simply be floated on top of the OSB subfloor.

3. PARTICLE BOARD

Particle board, also known as chip board, is made from compressed wood chips and resin and is more common in older homes.

Particle board subfloors are not ideal for holding nails and staples. The preferred method of installation above a particle board subfloor is a floating installation. Solid hardwood is not recommended for particle board. If you're looking to purchase engineered hardwood floors, be sure to check the specifications of the exact product, to ensure floating installation is approved.

There is also the option of adding a layer of plywood on top of a particle board subfloor in order to strengthen the foundation for your finished flooring, without having to replace the particle board subfloor, which will significantly expand your flooring options.

LVP floors are again floated, and approved for particle board subfloor installation.

4. CONCRETE

Concrete is an extremely durable, solid subfloor that comes with a number of advantages, including stiffness, cost and speed of construction, thermal comfort, energy efficiency, and more. The main thing to be cognizant of when installing finished flooring on top of a concrete subfloor is that concrete is permeable. Moisture, also referred to as "vapor," from the ground below the concrete will pass through the concrete into your home. Regardless of whether or not a moisture/vapor barrier was used beneath the concrete, it is always recommended to lay an additional moisture barrier, a 6-mil plastic sheeting, on top of concrete subfloors.

Be sure to review the manufacturer's installation guidelines for your particular product for instructions on how to prepare and install over a concrete subfloor. In most cases, as long as the concrete has been properly sealed, moisture levels measured and accounted for, and the concrete slab is level and dry, both hardwood and LVP floors can be installed above concrete with its respective, approved methods.